Learn more about MujinOS

Learn about the platform powering today's most advanced automation applications

Blogs

Blogs

MujinOS makes palletizing automation no-code, adaptive, and scalable – from single-SKU to mixed-case

Follow us

Follow us

Have a question?

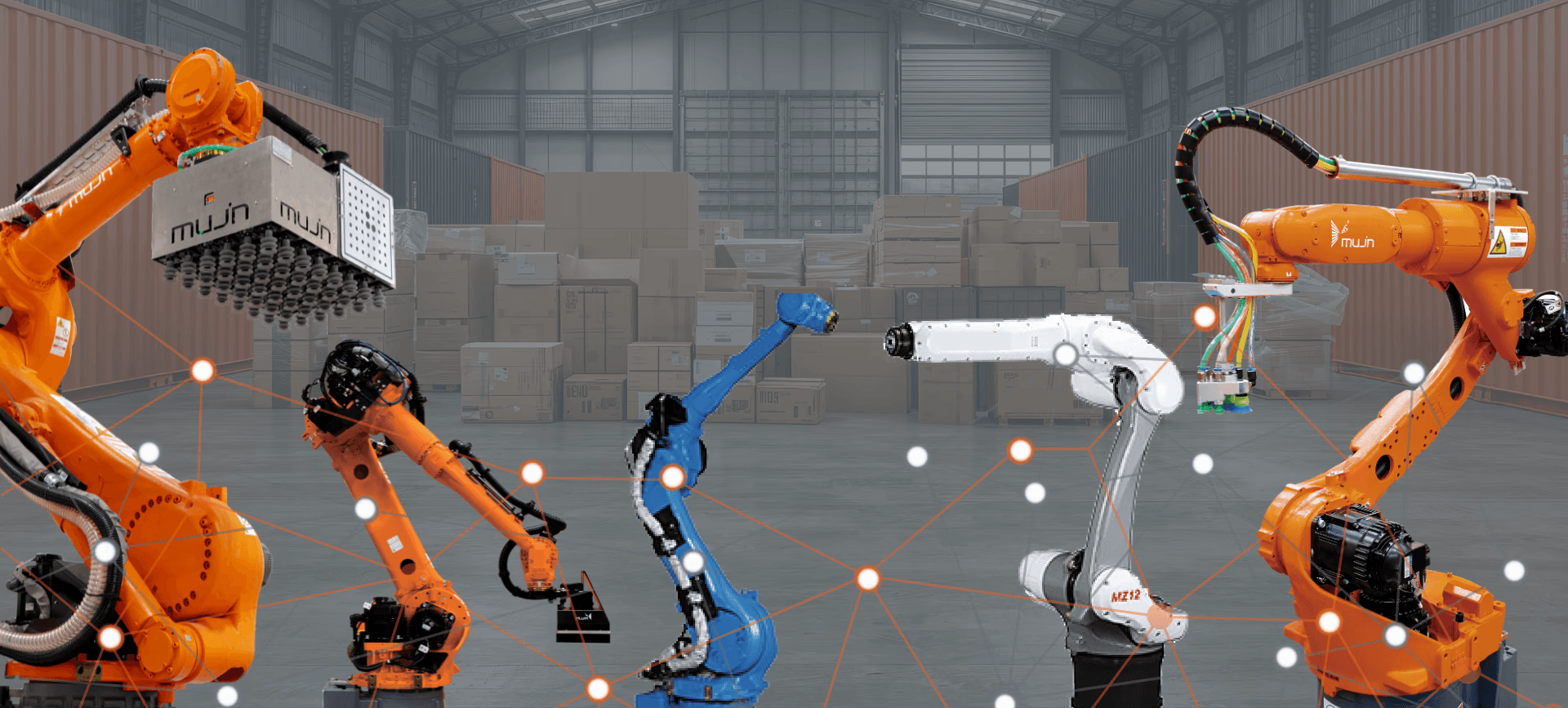

Learn how MujinOS delivers real-time perception, motion control, and no-code deployment—across any robotic system

Have a question?

Learn how MujinOS delivers real-time perception, motion control, and no-code deployment—across any robotic system